Installation

Installation

Each sheet edge receives a coating of urethane before the next pad is fixed in place. This provides a virtually seamless finish.

Door frames, windows, inspection hatches and wall pads, where necessary, have a special 45 degree angle fillet fitted. All exposed or wide joins receive special two part resin filling.

Once cured all surfaces are sanded and then painted with Gold Medal special urethane Top Coat. The finished room is completely sealed and virtually seamless.

To ensure the quality and integrity of Gold Medal Safety Padding is maintained, installers must have undertaken specific training and achieved “Approved Installer Classification”.

Rooms can be used within 36 hours of installation.

For use in:

- Correctional Facilities

- Police Stations

- Court Houses

- Remand Centres

- Juvenile Detention Centres

- Special Purpose Health Facilities

- Hospitals

- Mental Health Units

- Emergency Departments

- Secure Environments

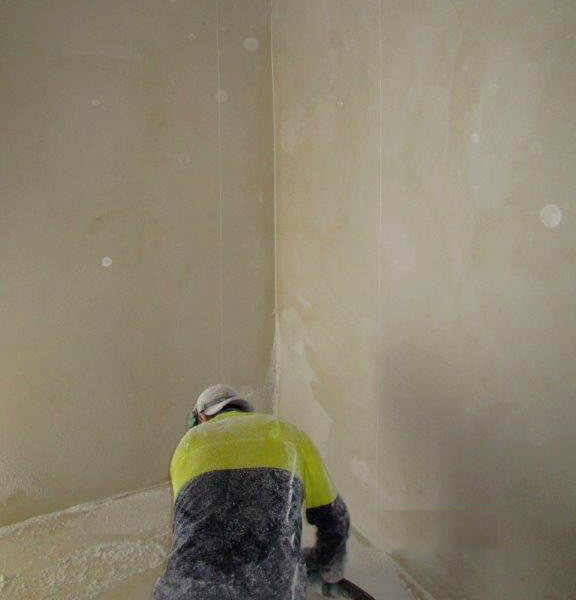

Wall pads are fixed with construction adhesive and nailed or screwed to a wall through the pad using the timber backing board as a fixing plate.

Each sheet edge receives a coating of urethane before the next pad is fixed in place. This provides a virtually seamless finish.

Door frames, windows, inspection hatches and wall pads, where necessary, have a special 45 degree angle fillet fitted. All exposed or wide joins receive special two part resin filling.

Once cured all surfaces are sanded and then painted with Gold Medal special urethane Top Coat. The finished room is completely sealed and virtually seamless.

To ensure the quality and integrity of Gold Medal Safety Padding is maintained, installers must have undertaken specific training and achieved “Approved Installer Classification”.

Rooms can be used within 24 hours of installation.

Safe Use and Care

Whenever a person is placed in a Personal Safety Room they should have undergone a complete body search and not have any items on them that can be used to cause damage to the padding such as belts, shoes, etc. Ultimately they would be placed in the room in only undergarments and a gown.

After a room has been used a visual check must be carried out to identify any signs of damage that may have been inflicted during its occupation. Any damage should be reported and repaired immediately to prevent further, possibly serious, damage.

Gold Medal Safety Padding is completely water and fungus resistant, therefore it can be hosed off, cleaned with any type of detergent and can be scrubbed with soft nylon brushes, without affecting its performance.

Anti-bacterial wipes are a suitable way of cleaning the room frequently without the requirement of introducing water. If the floor of the room has a drain fitted, ensure that the drain is clear. Standing water must be dried off using a dry mop after cleaning. Never allow water to stand on the product.

Repair

A major feature that sets Gold Medal Safety Padding apart from any competitor is the ability for local maintenance crews to carry our minor repairs. We can supply standard kits with full instructions on dealing with minor damage.

This ensures it is unnecessary to pay or wait for specialist repairers.

This demonstrates significant savings in repair and down time costs that have normally been associated with “Padded Rooms” and more than justifies the initial cost outlay.

We recommend that each room has an annual inspection to ensure all seams and finishes are in order.